hnachaj

Well-known member

- Joined

- Aug 30, 2011

- Messages

- 396

I had the opportunity to visit RC Cartridges in Forli not far from where I was staying, Ravenna. Alessandra Socci gave full access to all aspects of the plant, including quality control. Wads are mostly B&P with some Dana. Hulls are Cheditte. Powders come from B&P and a Scandinavian manufacturer that I have forgoten the name. For the RC Red line, they developed a new powder in alliance withe the Scandinavian manufacturer that has softer felt recoil while maintaining speed. Lead comes from Italy and China. Steel pellets are from China. They check every shipment of components before accepting the shipment. They have refused powders often and components occasionally. The shell boxes are made to food standards. They are more rigid and are waxed, so not affected by humidity changes. The company stresses Quality Control and consistency. The shell must have the same performance levels in Norway as in Dubai. They check every machine's production, every 30 minutes. So, if the machine loads 4 cartridges at a time, they take four off the line to the lab. I saw .1% difference in pellet weight. That is one to two pellets! Unheard of!This BSM machine produces 90,000 cartridges a day:

Here is part of the automatic packaging system that three BSM machines feed:

Here is part of the automatic packaging system that three BSM machines feed:

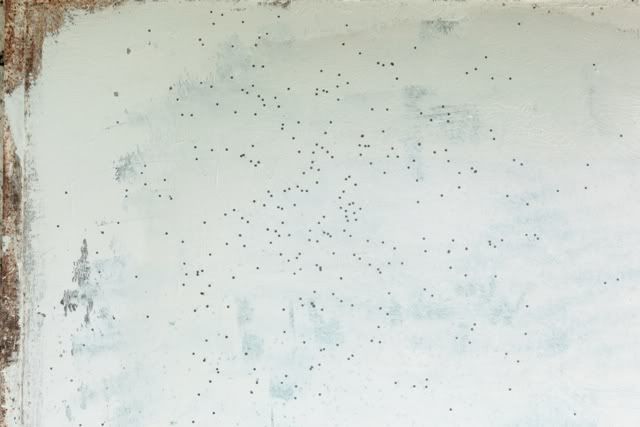

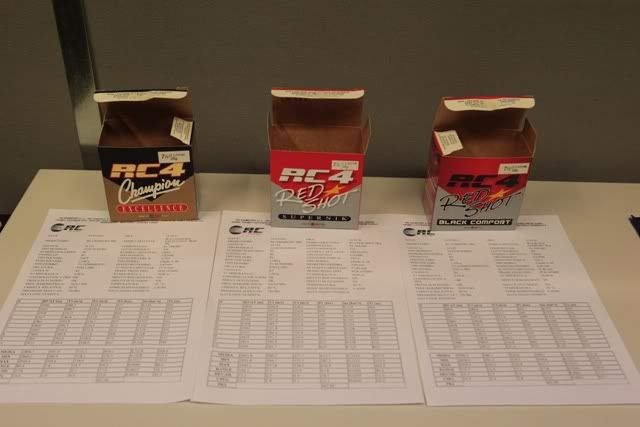

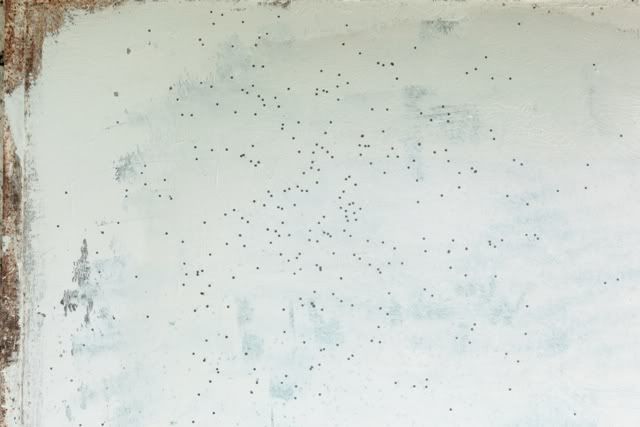

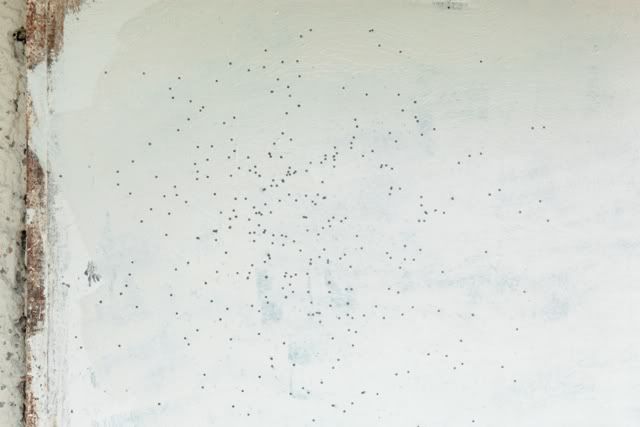

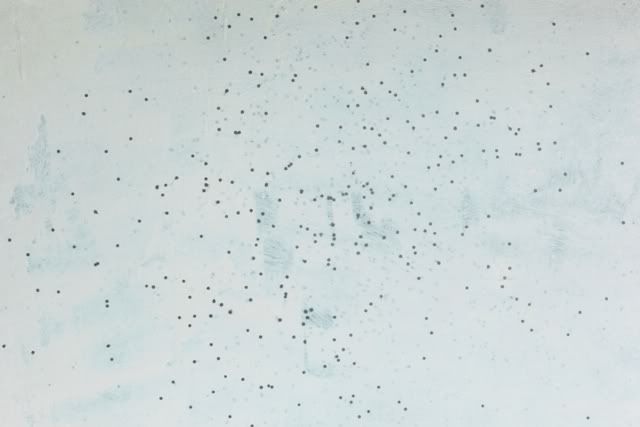

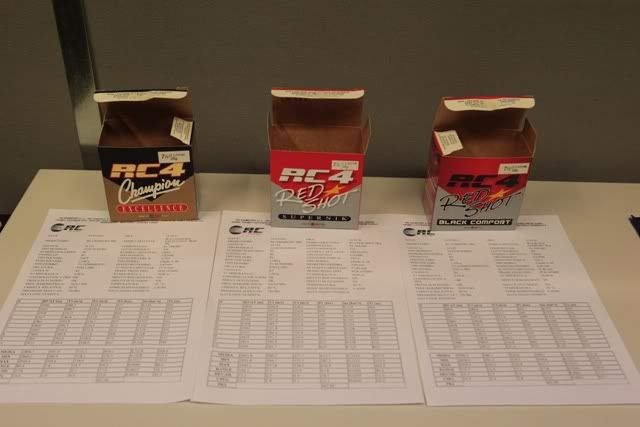

Here are the patterns all shot with my DT10L with a Muller U3 choke, about half choke for you blokes.

Here are the patterns all shot with my DT10L with a Muller U3 choke, about half choke for you blokes.

First RC4 Excellence Trap 7.5 (English 6.5?) 28gr

First RC4 Excellence Trap 7.5 (English 6.5?) 28gr

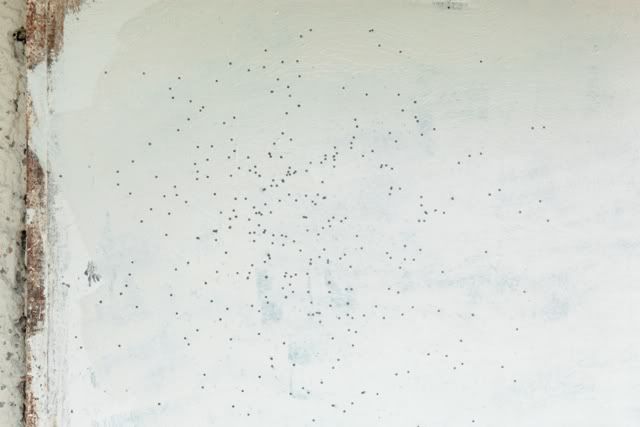

This is the RC Red Black Comfort 28Gr 7.5

This is the RC Red Black Comfort 28Gr 7.5

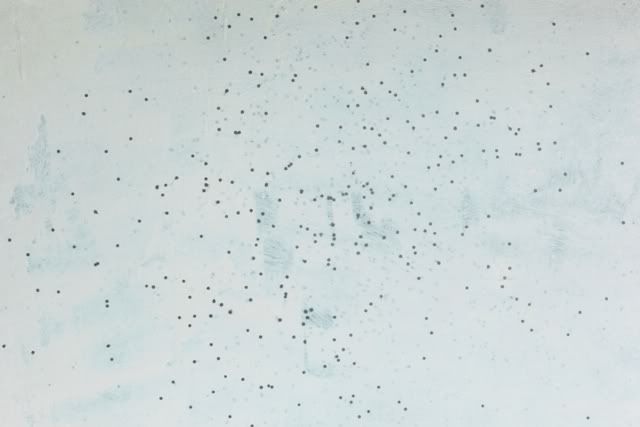

RC Red Supernik 28Gr 7.5

RC Red Supernik 28Gr 7.5

While we left with Alessandra and her husband Stefano for an excellent lunch at a local trattoria, the plant engineer took 10 samples from each box that I shot and put it through the lab.

While we left with Alessandra and her husband Stefano for an excellent lunch at a local trattoria, the plant engineer took 10 samples from each box that I shot and put it through the lab.

The recoil curve is not as steep as others that I have seen. It shows the push and not kick pressure. Here are the results:

The recoil curve is not as steep as others that I have seen. It shows the push and not kick pressure. Here are the results:

Velocities are read at the front of the shot cloud at 2.5M and 10M. In NA, we measure at 3 feet the average of the front and back of the shot cloud. The pressure is in Bar but it is a bit complex to translate into CUP. You can use an App to give you PSI.RC4 Excellence Trap 1282 fps 1090 fps Standard deviation 8.8fps 609.2 Bar SD 18 BarRC Red Blk Comfort 1266.7 fps 1065 fps SD 11.5 fps 590.9 Bar SD18RC Red Supernik 1278.5 fps 1087.6 fps SD 8.2 fps 590.9 Bar SD 18 BarThe pressure levels have only a .03 difference between shells. Meanwhile Standard deviation 11.5 fps and less are unheard of. SAAMI standards let manufacturers get away with 90 fps. In over thirty years of testing ammunition, I have yet to find a manufactured round having less than 20 fps SD, until now! "The proof is in the pudding"! RC makes the most consistent shell in the World. Let the facts speak for themselves. No other shot shell manufacturer has let anyone do what I did with my shotgun and watching them do QC and lab work. They did have a few nervous looking faces when I shot the patterns (I shot many more with more open chokes). But, the results were excellent.The RC Red Blk and the Supernik use the same amount of powder. The speed difference is due to the nickel plating (which does NOTHING for hardness) lets the pellets align themselves easier due to the lubrifying effect of nickel. The Lone Canadian,Henry/wp-content/forum-smileys/sf-wink.gif

Velocities are read at the front of the shot cloud at 2.5M and 10M. In NA, we measure at 3 feet the average of the front and back of the shot cloud. The pressure is in Bar but it is a bit complex to translate into CUP. You can use an App to give you PSI.RC4 Excellence Trap 1282 fps 1090 fps Standard deviation 8.8fps 609.2 Bar SD 18 BarRC Red Blk Comfort 1266.7 fps 1065 fps SD 11.5 fps 590.9 Bar SD18RC Red Supernik 1278.5 fps 1087.6 fps SD 8.2 fps 590.9 Bar SD 18 BarThe pressure levels have only a .03 difference between shells. Meanwhile Standard deviation 11.5 fps and less are unheard of. SAAMI standards let manufacturers get away with 90 fps. In over thirty years of testing ammunition, I have yet to find a manufactured round having less than 20 fps SD, until now! "The proof is in the pudding"! RC makes the most consistent shell in the World. Let the facts speak for themselves. No other shot shell manufacturer has let anyone do what I did with my shotgun and watching them do QC and lab work. They did have a few nervous looking faces when I shot the patterns (I shot many more with more open chokes). But, the results were excellent.The RC Red Blk and the Supernik use the same amount of powder. The speed difference is due to the nickel plating (which does NOTHING for hardness) lets the pellets align themselves easier due to the lubrifying effect of nickel. The Lone Canadian,Henry/wp-content/forum-smileys/sf-wink.gif

Last edited by a moderator: